FV Bearing is a leading supplier of precision bearings and bearings related products across a large spectrum of customers – preimarily OEMs and major distributors.

- +86-186-38891360

- sales@fv-bearing.com

- 7x24 Hours

Sendzimir mill bearing, Back-up Roller bearing

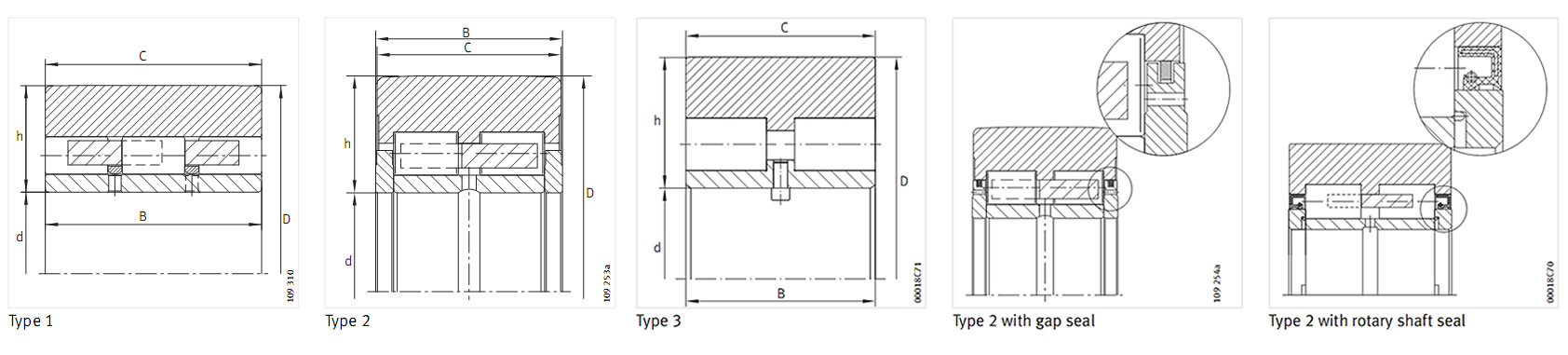

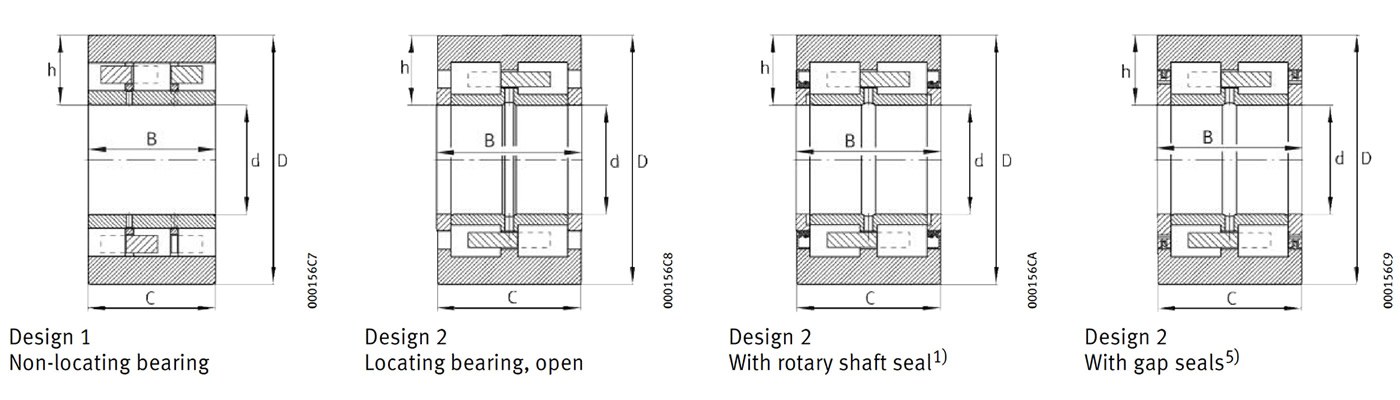

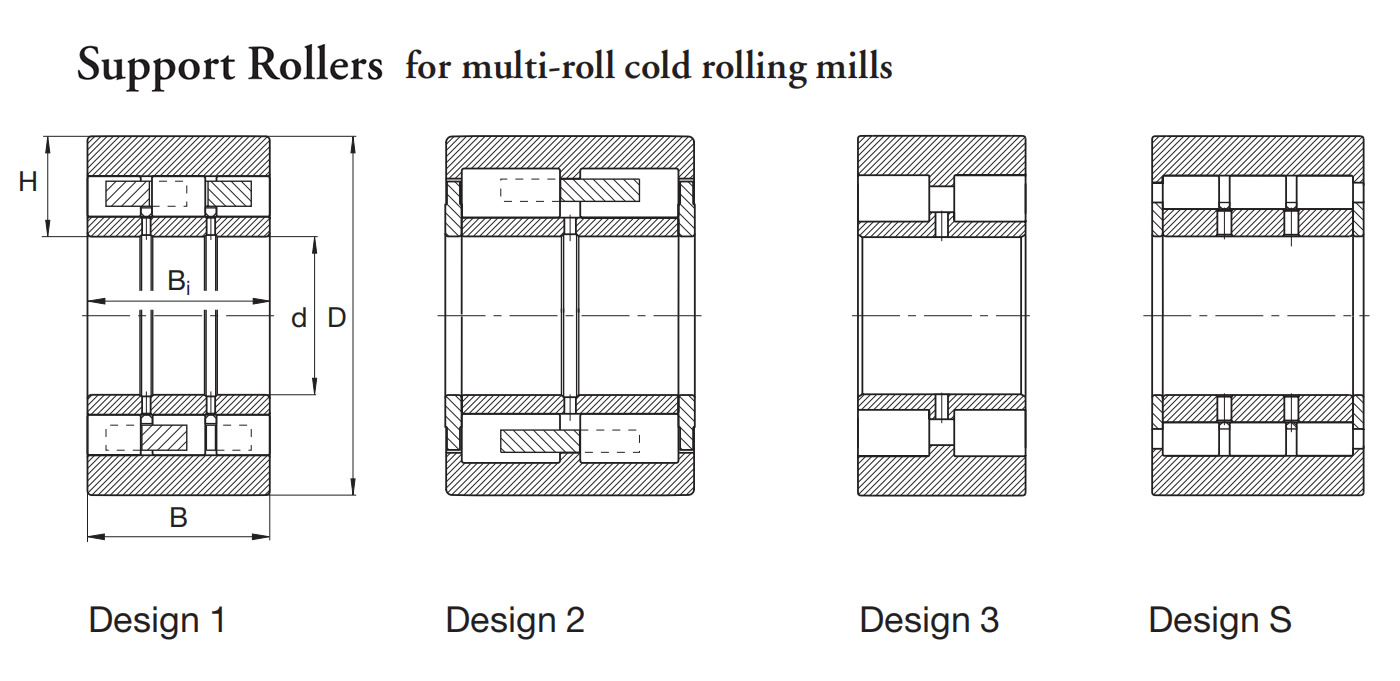

Multi-roll cold rolling mills process high-grade steel and non-ferrous metal strips. Intermediate rolls and support shafts provide support to prevent the work rolls from whipping. Multiple backup rollers are positioned next to one another on support shafts and kept apart by support saddles. This arrangement guarantees the proper distribution of roll load. Depending on their type, backup rollers can support high radial or axial forces transmitted to the stand via the adjacent structure.

Senzimir Bearing is a high-end product of metallurgical bearings. Due to the high technical difficulty, Senzimir bearings will experience large internal contact stress and outer ring contact deformation when subjected to large rolling forces and high linear speeds. Despite this, Sendzimir Bearings remains in the backup roller bearing market.

Manufacturers use different terms to describe multi-roll cold mill stands.

■ 12 and 20 roll stand

■ Z-High.

■ S-High.

Multi-roll cold rolling mills process high-grade steel strips and non-ferrous metal strips. Intermediate rolls and support shafts support them to prevent the work rolls from whipping. Several backup rollers are situated next to the support shafts, separated by support saddles, allowing for the necessary distribution of roll load. Depending on their type, backup rollers can support high radial or axial forces transmitted to the stand via the adjacent construction.

Several factors influence the quality of the rolled metal sheet. These include the bending rigidity of the support shaft, the section height tolerance, the running accuracy, and the surface quality of the outer ring outside the surface of the individual backup rollers.

Backup rollers

The rolling mill produces sheets with very precise tolerances, meaning that the sheets have a high running accuracy, better than P4. The sheets are grouped into three to seven-section height groups, ranging from 3um to 5um. These sheets are designed to handle high loads and accommodate strip speeds of up to 1000m/min, depending on the operating conditions. Three types of sheets are available, each manufactured to provide the highest surface quality and flatness standard for the rolled products. With this cutting-edge technology, you can achieve top-notch surface quality and precise thickness tolerances in sheet metal production without breaking the bank.

The model list can replace FAG model:

| Designation | Dimensions | Basic load ratings (kN) | Type | Mass | |||||||

| d | D | B | C | Section height (H) | dyn. C | stat. Cq | dyn. Cw | stat. CQw | kg | ||

| WGTR 25X55X31.2 | 25 | 55 | 31,2 | 30,5 | 15 | 39 | 42 | 30 | 33 | 2 | 0,4 |

| WGTR 35X80X40 | 35 | 80 | 40 | 39,2 | 22,5 | 89 | 103 | 69 | 81 | 2 | 1,2 |

| F-82547 | 45 | 125 | 78 | 77,5 | 40 | 275 | 325 | 225 | 295 | 2 | 5,6 |

| WGTR 55X120X52 | 55 | 120 | 52 | 51,2 | 32,5 | 168 | 218 | 123 | 158 | 2 | 3,4 |

| WGTR 55X120X64 | 55 | 120 | 64 | 63,2 | 32,5 | 215 | 300 | 155 | 213 | 2 | 4,2 |

| F-560123.01 | 55 | 126,02 | 64 | 63 | 35,5 | 212 | 295 | 163 | 243 | 2 | 4,6 |

| F-566100.01 | 60 | 150 | 75 | 73 | 45 | 270 | 335 | 222 | 310 | 2 | 7,9 |

| WGTR 70X160X75 | 70 | 160 | 75 | 74,2 | 45 | 295 | 380 | 231 | 300 | 2 | 8,9 |

| WGTR 70X160X90 | 70 | 160 | 90 | 89,2 | 45 | 395 | 550 | 300 | 425 | 2 | 10,7 |

| F-566567.01 | 70 | 165 | 90 | 88 | 47.5 | 400 | 560 | 310 | 460 | 2 | 10,7 |

| F-565718.01 | 70,02 | 160 | 90 | 89 | 44.988 | 395 | 550 | 300 | 425 | 2 | 10,7 |

| Z-540268.02.WGTR | 70 | 160.02 | 90 | 90 | 44.971 | 375 | 650 | 285 | 490 | 1 | 11,4 |

| Z-541332.01.WGTR | 90 | 220.02 | 94 | 94 | 65 | 620 | 870 | 455 | 680 | 3 | 21 |

| Z-541332.02.WGTR | 90 | 220.02 | 94 | 94 | 65 | 740 | 1100 | 530 | 800 | 3-VR4) | 21 |

| F-801941.WGTR | 90 | 220.02 | 96 | 94 | 65 | 550 | 780 | 415 | 600 | 2 | 22,2 |

| Z-567709.01.WGTR | 90 | 220.02 | 96 | 94 | 65 | 460 | 630 | 360 | 510 | 2 | 20 |

| F-808398.WGTR | 90 | 220.02 | 120 | 120 | 65,01 | 670 | 1120 | 485 | 800 | 5) | 28,5 |

| Z-517329.01.WGTR | 90 | 220.02 | 120 | 120 | 65 | 790 | 1500 | 540 | 990 | 5) | 28,6 |

| F-550356.01.WGTR | 90 | 220.02 | 122 | 119 | 65 | 710 | 1030 | 530 | 770 | 2 | 27,1 |

| F-801644.02.WGTR | 100 | 225 | 120 | 119 | 62.5 | 770 | 1310 | 560 | 930 | 2-VR4) | 26 |

| F-801644.03.WGTR | 100 | 225 | 120 | 119 | 62.5 | 650 | 1050 | 485 | 780 | 2 | 26 |

| Z-566148.WGTR | 100 | 225 | 120 | 119 | 62.5 | 710 | 1170 | 520 | 850 | 2 | 26 |

| Z-543638.02.WGTR | 100 | 225 | 120 | 120 | 62.5 | 735 | 1380 | 530 | 970 | 1 | 27.7 |

| Z-575633.WGTR | 110 | 260 | 98 | 98 | 75 | 700 | 1010 | 510 | 760 | 2 | 31.9 |

| WGTR 25X55X31,2 | 25 | 55 | 31,2 | 30.5 | 15 | 39 | 42 | 30 | 33 | 2 | 0,4 |

| WGTR 35X80X40 | 35 | 80 | 40 | 39.2 | 22,5 | 89 | 103 | 69 | 81 | 2 | 1.2 |

| F-82547 | 45 | 125 | 78 | 77.5 | 40 | 275 | 325 | 225 | 295 | 2 | 5.6 |

| WGTR 55X120X52 | 55 | 120 | 52 | 51.2 | 32.5 | 168 | 218 | 123 | 158 | 2 | 3.4 |

| WGTR 55X120X64 | 55 | 120 | 64 | 63.2 | 32.5 | 215 | 300 | 155 | 213 | 2 | 4,2 |

| F-560123.01 | 55 | 126,02 | 64 | 63 | 35.5 | 212 | 295 | 163 | 243 | 2 | 4.6 |

| F-566100.01 | 60 | 150 | 75 | 73 | 45 | 270 | 335 | 222 | 310 | 2 | 7.9 |

| WGTR 70X160X75 | 70 | 160 | 75 | 74.2 | 45 | 295 | 380 | 231 | 300 | 2 | 8,9 |

| WGTR 70X160X90 | 70 | 160 | 90 | 89.2 | 45 | 395 | 550 | 300 | 425 | 2 | 10,7 |

| F-566567.01 | 70 | 165 | 90 | 88 | 47.5 | 400 | 560 | 310 | 460 | 2 | 10,7 |

| F-565718.01 | 70,02 | 160 | 90 | 89 | 44.988 | 395 | 550 | 300 | 425 | 2 | 10,7 |

| Z-540268.02.WGTR | 70 | 160,02 | 90 | 90 | 44.971 | 375 | 650 | 285 | 490 | 1 | 11,4 |

| Z-541332.01.WGTR | 90 | 220,02 | 94 | 94 | 65 | 620 | 870 | 455 | 680 | 3 | 21 |

| Z-541332.02.WGTR | 90 | 220,02 | 94 | 94 | 65 | 740 | 1100 | 530 | 800 | 3-VR4) | 21 |

| F-801941.WGTR | 90 | 220,02 | 96 | 94 | 65 | 550 | 780 | 415 | 600 | 2 | 22,2 |

| Z-567709.01.WGTR | 90 | 220,02 | 96 | 94 | 65 | 460 | 630 | 360 | 510 | 2 | 20 |

| F-808398.WGTR | 90 | 220,02 | 120 | 120 | 65.01 | 670 | 1120 | 485 | 800 | 5) | 28,5 |

| Z-517329.01.WGTR | 90 | 220,02 | 120 | 120 | 65 | 790 | 1500 | 540 | 990 | 5) | 28,6 |

| F-550356.01.WGTR | 90 | 220,02 | 122 | 119 | 65 | 710 | 1030 | 530 | 770 | 2 | 27,1 |

| F-801644.02.WGTR | 100 | 225 | 120 | 119 | 62,5 | 770 | 1310 | 560 | 930 | 2-VR4) | 26 |

| F-801644.03.WGTR | 100 | 225 | 120 | 119 | 62,5 | 650 | 1050 | 485 | 780 | 2 | 26 |

| Z-566148.WGTR | 100 | 225 | 120 | 119 | 62,5 | 710 | 1170 | 520 | 850 | 2 | 26 |

| Z-543638.02.WGTR | 100 | 225 | 120 | 120 | 62,5 | 735 | 1380 | 530 | 970 | 1 | 27,7 |

| Z-575633.WGTR | 110 | 260 | 98 | 98 | 75 | 700 | 1010 | 510 | 760 | 2 | 31,9 |

| 1) Case hardening steel. 2) Rolling bearing steel (chromium steel). 3) Shell hardened steel. 4) VR = full complement design. 5) Special type. 6) Rotary shaft seal. 7) Gap seal. | |||||||||||

Big-size Back-up rollers (Double row or multi-row) sendzimir bearings list

| Designation | Design | Mass | Dimensions | Basic load ratings (kN) | |||||||

| Bearing | Back-up roller | ||||||||||

| kg | d | D | B | C | h | dyn. Cr | stat. Cor | dyn. Crw | stat. Corw | ||

| Z-577888.WGTR | 2 1)2) | 54,9 | 130 | 300,02 | 130 | 129 | 85,01 | 1040 | 1 560 | 760 | 1180 |

| Z-578270.01.WGTR | 2 2) | 56,5 | 130 | 300,02 | 132 | 129 | 85,01 | 1040 | 1 560 | 760 | 1180 |

| Z-564604.WGTR | 2 2) | 60 | 130 | 300,02 | 150 | 149 | 85 | 1200 | 1860 | 890 | 1450 |

| Z-548963.WGTR | 2 1)2) | 67,4 | 130 | 300,02 | 161,5 | 160,5 | 85 | 1200 | 1880 | 910 | 1490 |

| Z-567455.01.WGTR | 2 2) | 71,3 | 130 | 300,02 | 172,65 | 171,6 | 85 | 1440 | 2370 | 1010 | 1680 |

| Z-567998.01.WGTR | 2 3)5) | 73,5 | 130 | 300,02 | 172,65 | 171,6 | 85,01 | 1440 | 2370 | 1010 | 1680 |

| Z-549722.WGTR | 2 2) | 73,6 | 130 | 300,02 | 172,65 | 171,6 | 85,01 | 1440 | 2370 | 1010 | 1680 |

| Z-549722.01.WGTR | 2 1)2) | 73,6 | 130 | 300,02 | 172,65 | 171,6 | 85,01 | 1440 | 2370 | 1010 | 1680 |

| Z-512497.03.WGTR | 1 2) | 74,8 | 130 | 300,02 | 172,64 | 172,6 | 84,955 | 1500 | 2700 | 1030 | 1810 |

| F-800115.01.WGTR | 2 1)2) | 132 | 180 | 406,42 | 171,04 | 170 | 113,143 | 1570 | 2650 | 1170 | 2040 |

| Z-564247.02.WGTR | 2 1)2) | 125 | 180 | 406,4 | 171,04 | 170 | 113,2 | 1710 | 3000 | 1250 | 2190 |

| Z-564247.WGTR | 2 2) | 125 | 180 | 406,4 | 171,04 | 170 | 113,2 | 1710 | 3000 | 1250 | 2190 |

| Z-527502.03.WGTR | 1 2) | 130 | 180 | 406,42 | 171,04 | 171 | 113,143 | 2080 | 3850 | 1420 | 2550 |

| Z-543307.01.WGTR | 1 3) | 130 | 180 | 406,42 | 171,04 | 171 | 113,2 | 2080 | 3850 | 1420 | 2550 |

| F-809717.WGTR | 2 4) | 136 | 180 | 406,42 | 176 | 170 | 113,2 | 1710 | 3000 | 1250 | 2190 |

| Z-514278.01.WGTR | 1 2) | 150 | 180 | 406,42 | 217 | 217 | 113,143 | 2500 | 4900 | 1720 | 3250 |

| F-804209.WGTR | 2 2)5) | 174 | 180 | 406,4 | 224 | 220 | 113,2 | 1910 | 3450 | 1420 | 2600 |

| Z-523247.02.WGTR | 1 2) | 169 | 180 | 406,42 | 224 | 224 | 113,2 | 2600 | 5100 | 1790 | 3350 |

| Z-523247.03.WGTR | 1 3) | 169 | 180 | 406,42 | 224 | 224 | 113,2 | 2600 | 5100 | 1790 | 3350 |

| 1) Sealing with rotary shaft seals for recirculating oil lubrication. 2) Chill hardened outer ring. 3) Outer ring made from case hardening steel. 4) Back-up roller made from rolling bearing steel (chromium steel). 5) Sealing with lamellar rings for minimal quantity lubrication. | |||||||||||

Newly supplemented model data sheet:

| FAG code | Dimension (mm) | Section height | Load rating (kN) | Belastung Max load (kN) | Mass | Design | Material outer ring | ||||

| bearing | support roller | ||||||||||

| d | D | B | Bi | H | C | C | Fr | kg | 1) | 2) | |

| 578167 | 70 | 160.02 | 89.2 | 90 | 45 | 320 | 280 | 320 | 10.5 | 2 D2 | W |

| 540268A | 70 | 160.02 | 90 | 90 | 44.971 | 455 | 415 | 475 | 10 | 1 VR | E |

| 574324 | 90 | 220.02 | 94 | 94 | 65 | 550 | 480 | 405 | 20.7 | 2 | W |

| 541332A | 90 | 220.02 | 94 | 94 | 65 | 630 | 550 | 425 | 21 | 3 | W |

| 801941 | 90 | 220.02 | 94 | 96 | 65 | 550 | 480 | 405 | 20.8 | 2 | W |

| 567709 | 90 | 220.02 | 94 | 96 | 65 | 455 | 425 | 390 | 20 | 2 D1 | W |

| 517329A | 90 | 220.02 | 120 | 120 | 65 | 800 | 695 | 600 | 22.8 | S VR | W |

| 801644 | 100 | 225 | 119 | 120 | 62.5 | 655 | 570 | 540 | 26 | 2 D1 | W |

| 566148 | 100 | 225 | 119 | 120 | 62.5 | 710 | 610 | 550 | 26 | 2 D2 | W |

| 543638A | 100 | 225 | 120 | 120 | 62.5 | 735 | 670 | 655 | 27.7 | 1 | W |

| 575633 | 110 | 260 | 98 | 120 | 75 | 695 | 600 | 490 | 30 | 2 | W |

| 577888 | 130 | 300.02 | 129 | 130 | 85.01 | 1040 | 880 | 720 | 52.7 | 2 D1 | W |

| 567998A | 130 | 300.02 | 171.6 | 172.65 | 85.01 | 1430 | 1180 | 1200 | 70 | 2 D2 | E |

| 549722 | 130 | 300.02 | 171.6 | 172.65 | 85.01 | 1430 | 1180 | 950 | 70 | 2 D2 | W |

| 801788 | 130 | 300.02 | 171.6 | 172.65 | 85 | 1430 | 1200 | 980 | 70 | 2 D1 | W |

| 564604 | 130 | 300.02 | 149 | 150 | 85 | 1140 | 1000 | 965 | 60 | 2 | W |

| 548963 | 130 | 300.02 | 160.5 | 161.5 | 85 | 1200 | 1060 | 950 | 63 | 2 D1 | W |

| 512497C | 130 | 300.02 | 172.64 | 172.64 | 84.955 | 1500 | 1340 | 1290 | 71.5 | 1 | SH |

| 512497D | 130 | 300.02 | 172.64 | 172.64 | 84.955 | 1500 | 1340 | 1040 | 71.5 | 1 | W |

| 567455A | 130 | 300.02 | 171.6 | 172.65 | 85 | 1430 | 1180 | 950 | 70 | 2 | W |

| 564247 | 180 | 406.4 | 170 | 171.04 | 113.2 | 1700 | 1460 | 1460 | 125 | 2 | W |

| 800115A | 180 | 406.42 | 170 | 171.04 | 113.143 | 1560 | 1370 | 1430 | 128 | 2 D1 | W |

| 527502B | 180 | 406.42 | 171.04 | 171.04 | 113.2 | 2080 | 1830 | 1500 | 130 | 1 | W |

| 527502C | 180 | 406.42 | 171.04 | 171.04 | 113.143 | 2080 | 1830 | 1860 | 1 30 | 1 | SH |

| 543307A | 180 | 406.42 | 171.04 | 171.04 | 113.2 | 2080 | 1830 | 1860 | 1 30 | 1 | E |

| 514278A | 180 | 406.42 | 217 | 217 | 113.143 | 2500 | 2200 | 2360 | 1 50 | 1 | SH |

| 523247B | 180 | 406.42 | 224 | 224 | 113.2 | 2550 | 2240 | 2450 | 169 | 1 | SH |

| 523247C | 180 | 406.42 | 224 | 224 | 113.2 | 2550 | 2240 | 2450 | 169 | 1 | E |

1) D1: sealing with shaft seals at oil lubrication or closed system grease lubrication D2: sealing with (Fey) lamellar rings at oil mist lubrication S: special design VR: full-complement design 2) E: case hardening steel SH: special hardening W: rolling bearing steel (chromium steel) | |||||||||||

A Leading Industrial Bearings Supplier

Why Choose FV Bearings?

Leading industrial ball bearings with best materials

FV Bearings uses best materials to produce high quality and precision ball bearings, deep groove ball bearings, thrust ball bearings and any other types of bearings. The company accept all bearings manufacturing and OEM services.

Accurate response to client’s request

FV Bearings Co.Ltd has rich experiences in bearings manufacturing and processing, the professional bearing engineers can handle your requirements on bearings exactly and output the accurate bearing products.

World’s leading roller bearings manufacturer

FV Bearings is a leading roller bearings manufacturer provides high quality and durable roller bearings for different industries such as automotive, aerospace, machinery, power plants, chemistry industry, agriculture and other fields.

Solutions for special bearings and high end bearings

If you are looking for special bearings and high end bearings, FV bearings can help you to customize any special bearings according to your needs based on advanced bearings manufacturing technology.